CC-Link IE TSNNEW!

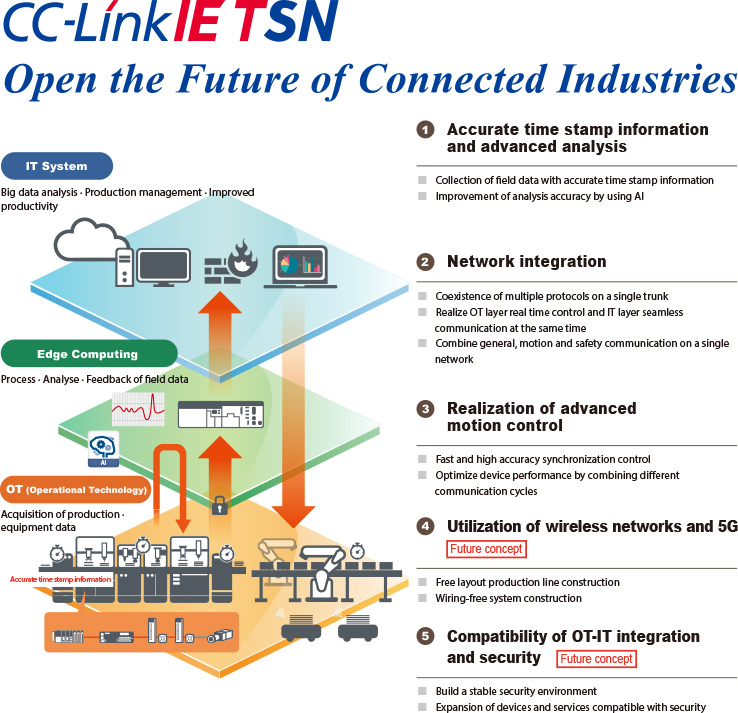

CC-Link IE TSN is the first to combine gigabit Ethernet bandwidth with Time-Sensitive Networking (TSN). It has increased openness while further strengthening performance and functionality.

Introduction to CC-Link IE TSN

CC-Link IE TSN adds TSN to increase openness while further strengthening performance and functionality.

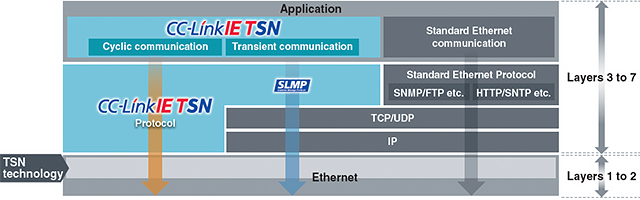

TSN technology and protocol layers

- CC-Link IE TSN's protocol uses layers 3 ~ 7of the OSI reference model, building on the TSN technology located in layers 2.

TSN (Time-Sensitive Networking)

TSN consists of multiple international standards. The major standards are IEEE802.1AS (which defines the time synchronization method) and IEEE802.1Qbv (which defines the time sharing method). Combining these with the Ethernet standard enables punctuality, ensuring transmission within a given period of time, and mixed implementation with other communication protocols.

Features

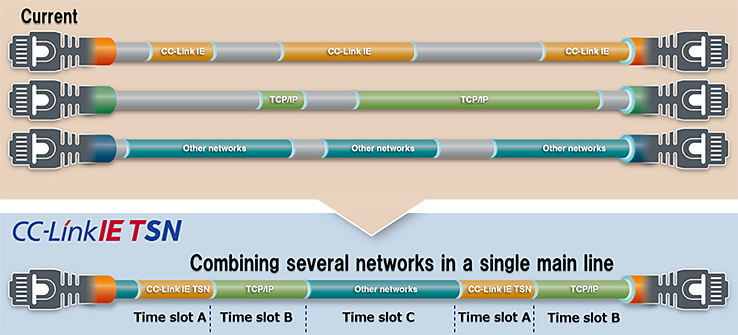

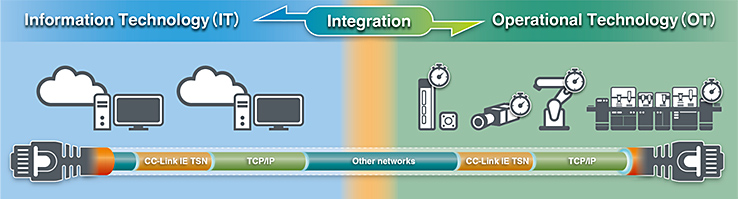

(1) Integration of OT and IT

- By enabling control communication that ensures real-time performance while integrating communication of other open networks and IT system information on the same network, it chieves the freedom of system configuration and significantly reduce wiring costs.

(2) Communication methods

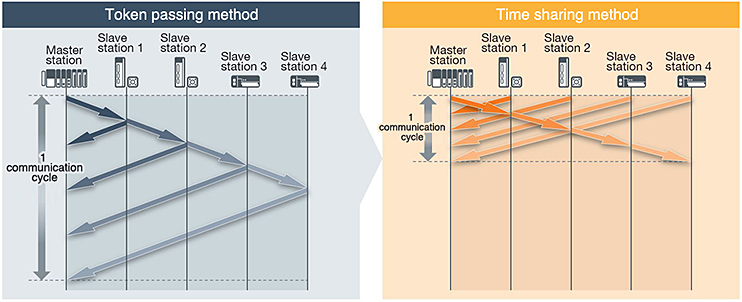

- Conventional CC-Link IE uses a token passing method. A station transfers transmission rights to the next station after transmitting its own data by transfer of the token.

- CC-Link IE TSN uses common time synchronized across the network. The input and output communication frames are simultaneously transmitted in both directions in a fixed time. Combining this method with TSN shortens the network cyclic data update time.

-

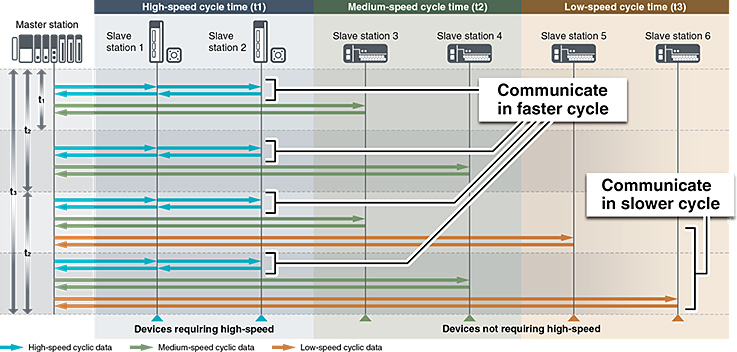

CC-Link IE TSN allows for multiple communication cycles to be used within the same network.

This makes it possible to maintain the device performance that require a high-performance communication cycle, such as servo amplifiers and connect devices that do not require a high-speed communication cycle, such as remote I / O, to match the characteristics of each device.

It can optimize the communication cycle, maximize the drive control performance, and shorten the tact time.

(3) Reduction of man-hours for start-up, operation, and maintenance

- CC-Link IE TSN also supports SNMP. With a general-purpose SNMP monitoring tool, both CC-Link IE TSN devices and IP communication devices such as switches and routers can be analysed together.

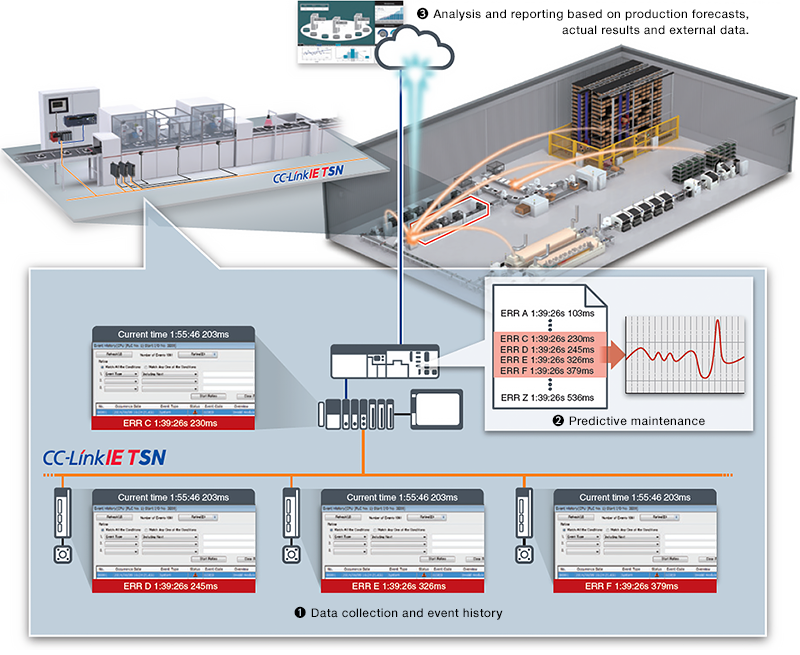

- The time synchronization protocol regulated by TSN is used to calibrate time differences between devices compatible with CC-Link IE TSN, keeping them synchronized with high accuracy. Time information stored in both master and slave devices is kept synchronized to the microsecond. If a network error occurs, this makes it possible to check operation logs and accurately trace events up to the error in chronological order.

- It is also possible to provide production site information and accurate time information to IT systems. This will allow AI enabled data analysis to provide further process improvement via predictive maintenance.

(4) Expansion of compatible products through various development methods

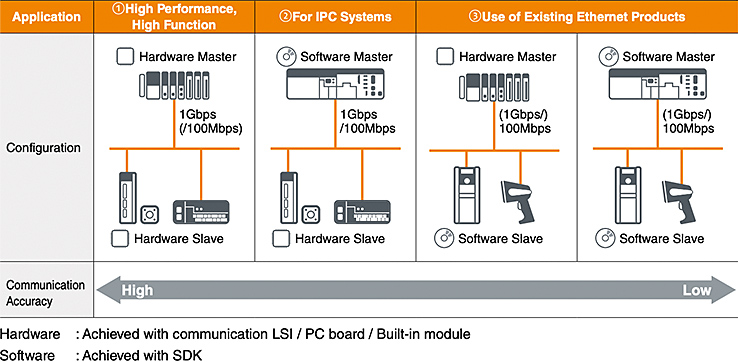

- CC-Link IE TSN supports implementation on both hardware and software platforms. ASIC and FPGA based hardware methods are supported. Moreover, development with software protocol stacks on a general purpose Ethernet chip is also possible for both master and slave devices. In all cases, 100Mbit and 1Gbit physical layers are supported.

- This flexibility permits device vendors to develop products by the most optimal methods while minimizing time to market. This results in a wider range of products for end users.

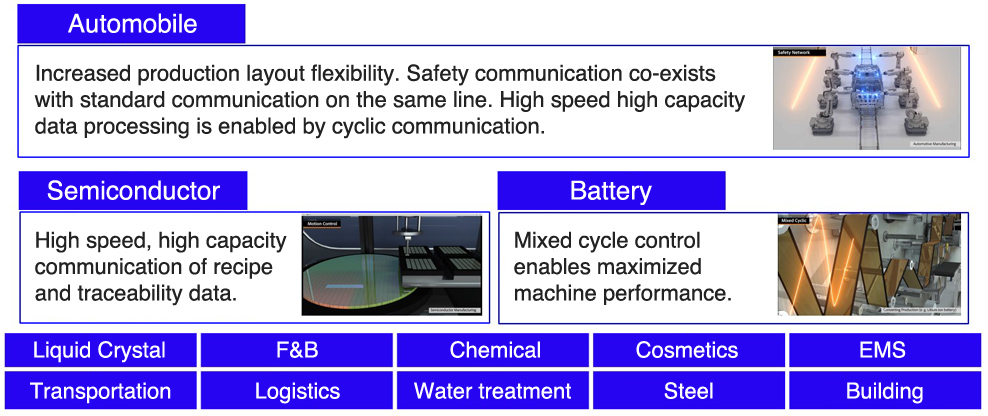

Use cases

By using TSN, CC-Link IE TSN will not only simplify the utilization of IP devices but also achieve high speed control communication due to a redesigned protocol suitable for various industries.

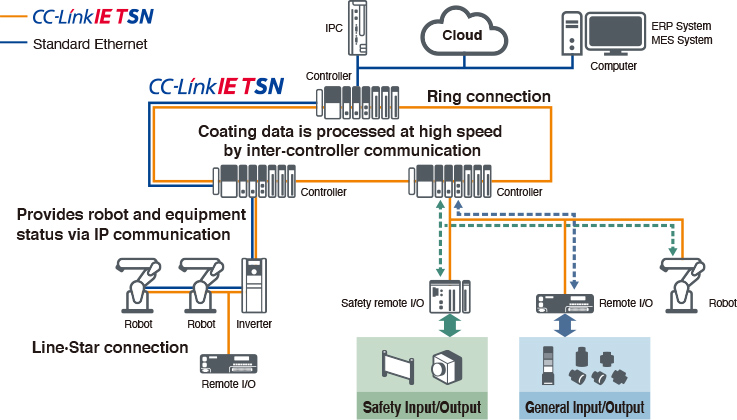

(1) Automotive (Paint shop)

- In the automobile painting process, it is possible to collect and analyze a large amount of data such as painting quality data and equipment monitoring data of painting robots at high speed with a higher-level controller. In addition, it is also possible to support variable production by sending a wide variety of recipe data to the equipment side in real time.

- Since general communication and secure communication can be mixed, wiring costs and wiring mistakes can be significantly reduced. By using the ring topology, it is possible to avoid equipment stoppage in the event of equipment trouble with the loopback function, and it is possible to reduce downtime.

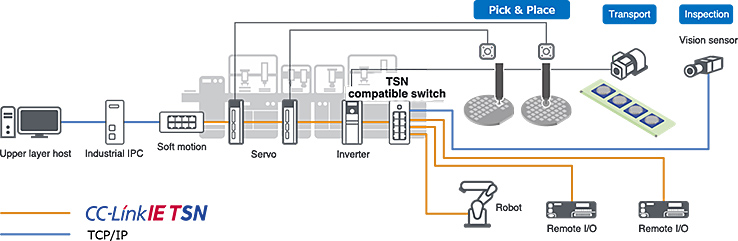

(2) Semiconductor manufacturing equipment (bonding)

- It is possible to communicate a large amount of information such as recipe data and traceability data at high speed without affecting control communication.

-

Even with IPC, which is the main controller for semiconductor devices, the master function of CC-Link IE TSN can be implemented by software without changing the existing hardware and it utilizes the current design assets.

This makes it possible to significantly reduce design man-hours.

- CC-Link Partner Association (CLPA)

Members Site